Our Process

Built to Plan

100% satisfaction. Zero uncertainty.

Construction has many moving parts, and AMS manages them all. We’re hands-on start to finish, streamlining every step to shorten schedules and control costs across the entire project lifecycle. Our collaborative approach brings multiple disciplines together as a dedicated team project-managed by AMS leadership. We partner with architects and stakeholders to spec a project to a school’s intent and vision, expertly managing all materials and services necessary to design and deliver buildings optimized for efficiency, usability and best practices. We take the uncertainty out of construction, ensuring every AMS building is built to plan and meets the highest quality, health and safety standards. Guaranteed.

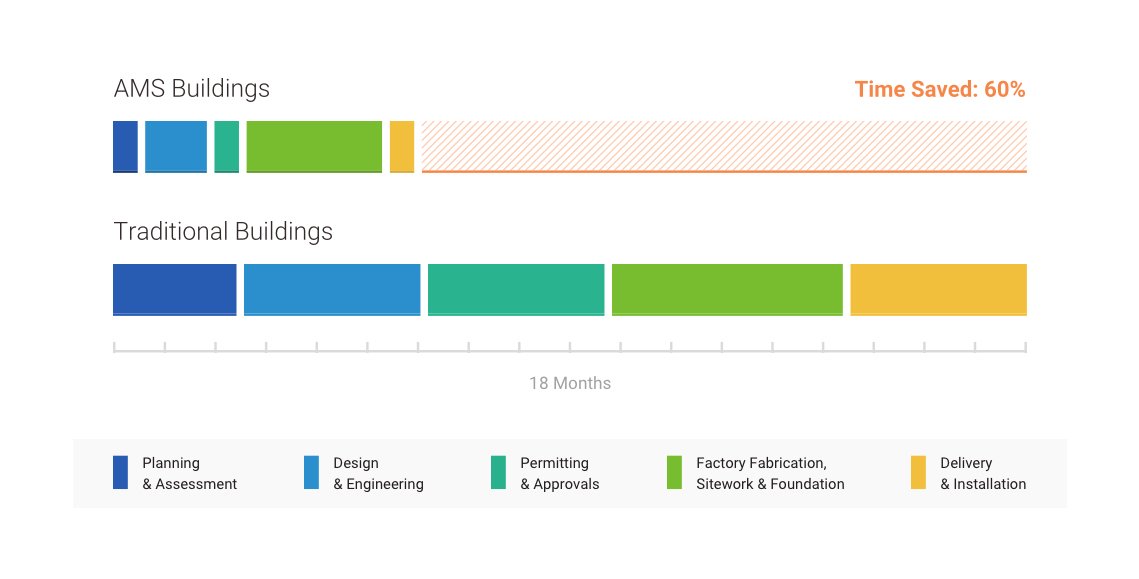

AMS Buildings vs. Traditional Buildings

Traditional buildings are built entirely onsite, which means construction can’t start until the sitework and foundation are finished—a process that can take months. AMS works in parallel, constructing buildings in our factory while the site contractor completes the sitework. A more efficient process allows AMS to deliver a same-spec building, built to the same codes, in less than half the time, for a fraction of the cost. Advantage: AMS.

Our streamlined 5-step process allows us to plan, design, permit, manufacture and deliver a superior quality building quickly, cost-effectively and customized to a school’s needs.

AMS’ precision-manufacturing process has been perfected over decades of use, streamlining costs and delivering the highest quality building on-time, on-budget and to-plan. That’s our commitment to every client—and it doesn’t stop when the building is delivered. We’ll follow up to make sure you’re happy with your building and will be a valuable resource to you over the building’s lifecycle.